Shipping calculator

Payment methods

Product details

Crosby Screw Pin Anchor Shackles

Screw pin shackles are designed to offer the security of a strong connection with the ease of a quick-release pin. The bow shape has the ability to handle a wider variety of connections.

The Crosby screw pin shackle is ideal for temporary lifting jobs or those that require frequent connects and disconnects, i.e.Pick a load and place. It can be used for applications involving side loading with the required reduction of Working Load Limits.

With an easy-to-use QUIC-CHECK features, the angle indicators are forged into the shackle bow at 45-degree angles from vertical, allowing users to quickly check the approximate angle of a 2-legged hitch or the angle of a single leg hitch when the pull of the load is off vertical (side-loaded). The reduction in the WLL of the shackle can then be quickly applied.

Note: For long-term or permanent installation, a bolt shackle is recommended. For more details, please check the 'Specification' section below or the Crosby Shackle Datasheet here.

FEATURES

- Forged - Quenched and Tempered, with alloy pins.

- Working Load Limit and grade “6” permanently shown on every shackle.

- Hot Dip Galvanized(G-209) / Red-Painted(S-209)

- Fatigue rated.

- Shackles 25t and larger are RFID EQUIPPED.

- Capacities: 1/3 thru 55 metric tons, grade 6.

-

Temperature for use:

- Approved for use at -40 degrees C (-40 degrees F) to 204 degrees C (400 degrees F).

- All 209 and 210 shackles can meet Charpy requirements of 42 joules(31 ft-lbs) avg. at -20 degrees C (-4 degrees F) upon special request. -

Standard:

- Meet the performance requirements of Federal Specification RR-C-271G Type IVA, Grade A, Class 2.

- Meets or exceeds all requirements of ASME B30.26.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at the time of order and may include additional charges.

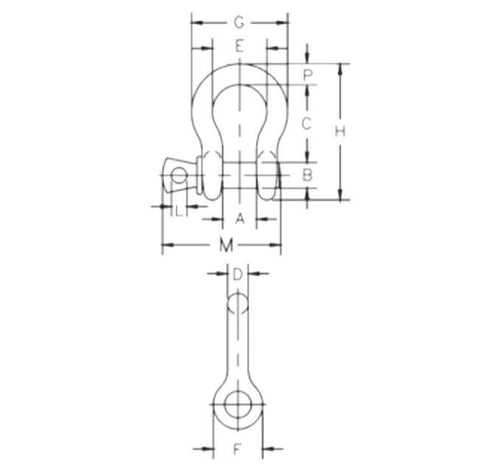

SPECIFICATIONS

| Dimensions (in) | Tolerance (+/-) | ||||||||||||||

| Nominal Size (in) | WLL (t) | Weight (lb) | A | B | C | D | E | F | G | H | L | M | P | C | A |

| 3/16 | 1/3 | 0.06 | 0.38 | 0.25 | 0.88 | 0.19 | 0.60 | 0.56 | 0.98 | 1.47 | 0.16 | 1.14 | 0.19 | 0.06 | 0.06 |

| 1/4 | 1/2 | 0.10 | 0.47 | 0.31 | 1.13 | 0.25 | 0.78 | 0.61 | 1.28 | 1.84 | 0.19 | 1.43 | 0.25 | 0.06 | 0.06 |

| 5/16 | 3/4 | 0.18 | 0.53 | 0.38 | 1.22 | 0.31 | 0.84 | 0.75 | 1.47 | 2.09 | 0.22 | 1.71 | 0.31 | 0.06 | 0.06 |

| 3/8 | 1 | 0.31 | 0.66 | 0.44 | 1.44 | 0.38 | 1.03 | 0.91 | 1.78 | 2.49 | 0.25 | 2.02 | 0.38 | 0.13 | 0.06 |

| 7/16 | 1-1/2 | 0.38 | 0.75 | 0.50 | 1.69 | 0.44 | 1.16 | 1.06 | 2.03 | 2.91 | 0.31 | 2.37 | 0.44 | 0.13 | 0.06 |

| 1/2 | 2 | 0.72 | 0.81 | 0.63 | 1.88 | 0.50 | 1.31 | 1.19 | 2.31 | 3.28 | 0.38 | 2.69 | 0.50 | 0.13 | 0.06 |

| 5/8 | 3-1/4 | 1.37 | 1.06 | 0.75 | 2.38 | 0.63 | 1.69 | 1.50 | 2.94 | 4.19 | 0.44 | 3.34 | 0.69 | 0.13 | 0.06 |

| 3/4 | 4-3/4 | 2.35 | 1.25 | 0.88 | 2.81 | 0.75 | 2.00 | 1.81 | 3.50 | 4.97 | 0.50 | 3.97 | 0.81 | 0.25 | 0.06 |

| 7/8 | 6-1/2 | 3.62 | 1.44 | 1.00 | 3.31 | 0.88 | 2.28 | 2.09 | 4.03 | 5.83 | 0.50 | 4.50 | 0.97 | 0.25 | 0.06 |

| 1 | 8-1/2 | 5.03 | 1.69 | 1.13 | 3.75 | 1.00 | 2.69 | 2.38 | 4.69 | 6.56 | 0.56 | 5.13 | 1.06 | 0.25 | 0.06 |

| 1-1/8 | 9-1/2 | 7.41 | 1.81 | 1.25 | 4.25 | 1.16 | 2.91 | 2.69 | 5.16 | 7.47 | 0.63 | 5.71 | 1.25 | 0.25 | 0.06 |

| 1-1/4 | 12 | 9.50 | 2.03 | 1.38 | 4.69 | 1.29 | 3.25 | 3.00 | 5.75 | 8.25 | 0.69 | 6.25 | 1.38 | 0.25 | 0.06 |

| 1-3/8 | 13-1/2 | 13.53 | 2.25 | 1.50 | 5.25 | 1.42 | 3.63 | 3.31 | 6.38 | 9.16 | 0.75 | 6.83 | 1.50 | 0.25 | 0.13 |

| 1-1/2 | 17 | 17.20 | 2.38 | 1.63 | 5.75 | 1.54 | 3.88 | 3.63 | 6.88 | 10.00 | 0.81 | 7.33 | 1.62 | 0.25 | 0.13 |

| 1-3/4 | 25 | 27.78 | 2.88 | 2.00 | 7.00 | 1.84 | 5.00 | 4.19 | 8.86 | 12.34 | 1.00 | 9.06 | 2.25 | 0.25 | 0.13 |

| 2 | 35 | 45.00 | 3.25 | 2.25 | 7.75 | 2.08 | 5.75 | 4.81 | 9.97 | 13.68 | 1.22 | 10.35 | 2.40 | 0.25 | 0.13 |

| 2-1/2 | 55 | 85.75 | 4.13 | 2.75 | 10.50 | 2.71 | 7.25 | 5.69 | 12.87 | 17.84 | 1.38 | 13.00 | 3.13 | 0.25 | 0.25 |

Note: Crosby screw pin shackles can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification. Proof testing and certification available when requested at the time of order, charges will apply.

- Choosing a selection results in a full page refresh.

- Opens in a new window.